When soundproofing a building, choosing the right insulation material is crucial. Two of the most popular options are Thermafiber and Rockwool. But which offers better sound absorption and insulation?

This guide examines the key differences between Thermafiber and Rockwool insulation for soundproofing. We compare performance factors like noise reduction, fire resistance, cost, sustainability and ease of installation.

Overview of Soundproofing Materials

Effective soundproofing blocks, absorbs or redirects noise vibrations before they transmit into adjoining areas. Materials like insulation batts, drywall, sound damping compounds and resilient channels help achieve this acoustic isolation.

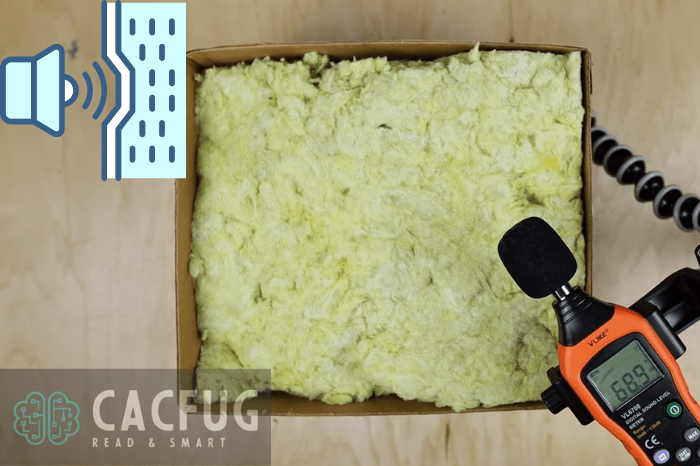

The best soundproof insulations have high density compositions, irregular and porous fiber structures to trap sound waves. They don’t corrode and offer thermal insulation as well.

Key Properties of Thermafiber

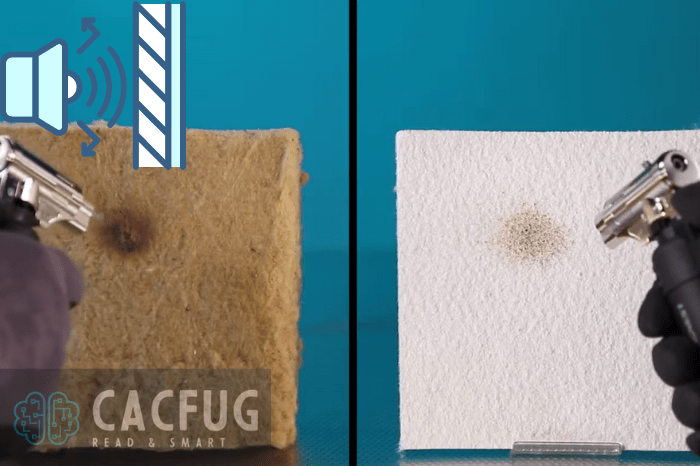

Thermafiber is a brand of stone wool fiber insulation made from basalt rock and recycled slag. High-temperature spinning creates a non-combustible, mineral wool insulation.

Its sound absorption properties, resistance to heat flow and lightweight make Thermafiber popular for interior wall soundproofing. Thermafiber products don’t promote mold growth and meet stringent codes for fire resistance.

Key Properties of Rockwool

Like Thermafiber, Rockwool is also a stone wool insulation made by melting volcanic rock such as basalt and spinning it into a fiber-like structure.

Its high density, randomly arranged fibers excellently dampen noise vibrations. Rockwool insulation is water repellant, non-combustible to 1000°C and resists bacterial or fungal growth.

Which Is Better: Thermafiber vs Rockwool Soundproofing?

When choosing soundproofing insulation, noise reduction capability is the prime consideration.

Overall, Rockwool and Thermafiber demonstrate similar sound dampening qualities based on their densities.

However, Rockwool panels tend to have slightly better NRC (Noise Reduction Coefficient) ratings indicating higher sound absorption especially in lower frequencies.

Ease of Installation

Both Rockwool and Thermafiber insulation batts are lightweight and easy to handle using basic PPE for skin and eye protection. Cutting doesn’t produce harmful dust. Thermafiber may be easier to cut cleanly to size.

For new drywall installation, Rockwool boards provide higher thermal resistance allowing thinner walls with weight savings. Thermafiber fitted between wall studs makes retrofitting existing drywall simpler.

Durability and Longevity

Properly installed, Thermafiber and Rockwool offer permanent noise insulation for building life cycles of 40-60 years.

Thermafiber may be more vulnerable to sagging from moisture absorption over decades. Rockwool retains its form better when exposed to water leakages. Both handle outdoor/freeze-thaw temperature cycling well.

Sustainability Comparison

Thermafiber utilizes a high amount of recycled content – up to 70%. Rockwool varies by product line but averages around 50%.

Both represent environmentally responsible options. They divert industrial waste from landfills. Off-gassing may occur during initial curing but isn’t a health hazard.

Cost Comparison

Rockwool frequently costs more upfront. But its higher R-values mean using thinner layers for equivalent sound dampening. Thermafiber is often the more budget-friendly option per square foot.

Conclusion

For soundproofing performance, Rockwool and Thermafiber offer comparable noise blocking abilities. Rockwool provides slightly better acoustic insulation metrics.

Thermafiber insulation may be better suited where fire resistance requirements are less stringent. Its easier workability and lower cost also appeal if walls require retrofitting.

Consult manufacturer guidelines specific to your project when selecting between these stone wool insulations. Proper installation is vital to harness their full sound dampening potential over time.